Jul 24,2025

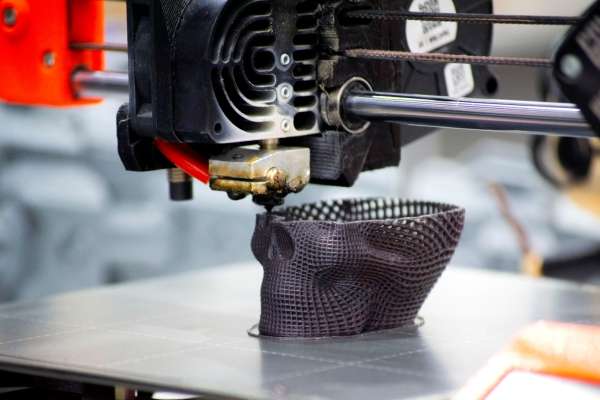

Small‑batch (or low‑volume) production generally refers to runs from a single prototype up to a few thousand identical parts. These orders are too large for one‑off prototyping services yet too small to amortize the tooling and set‑up costs of injection‑molding or die‑casting. Historically, manufacturers faced an uncomfortable choice: pay high per‑part costs to machine every unit individually, or commit tens of thousands of dollars to hard tooling that would never recoup its investment. Additive manufacturing—popularly known as 3D printing—resolves that dilemma by eliminating molds, shortening lead times, and allowing digital files to flow straight to production.

Because parts are built layer by layer directly from a CAD file, there is no need for aluminum or steel molds. Eliminating tooling removes one of the largest fixed costs in traditional manufacturing and slashes project start‑up time from weeks or months to mere hours. A 2024 Form labs study found that the breakeven point between 3D printing and injection molding now sits around 13,000 parts, with 3D printing costing 85 % less per part at volumes under 1,000.

Lead‑time reduction is critical for companies racing to validate new designs, secure early sales, or respond to market shifts. Portola’s’ 2024 Trend Report notes that 70 % of surveyed businesses printed more parts in 2023 than in 2022 specifically because additive methods let them compress development cycles.

When you need 50, 500 or 5,000 units, 3D printing avoids the “tooling tax.” Studies show that expensive molds only become cost-effective at high volumes; below that threshold, additive remains more economical, even if the raw material cost per part is higher.

Because layers can be deposited in virtually any geometry, engineers are free to incorporate internal channels, lattice infills for lightweighting, or organic shapes that would be impossible to machine or de‑mold. Design tweaks only require a new file upload—no re‑cutting tools or scrapping inventory. Companies therefore iterate multiple generations in days, tightening feedback loops between engineering, testing, and marketing.

Small batches can be printed as orders arrive, reducing the need to tie up capital in inventory. Digital files can be transmitted to any additive facility worldwide, enabling localized production close to the end‑user and mitigating geopolitical or logistics disruptions. Manufacturers increasingly view additive as a solution to build resilience and enable just‑in‑time strategies without overseas dependence.

Additive methods use only the material required for each part, cutting raw‑material waste by up to 90 % versus subtractive processes. New binder‑jet and recycled‑pellet printers accept sustainable powders or re‑grind, while local production trims transportation emissions. Sustainability is one of the biggest drivers of additive adoption today.

Today’s market spans polymers (SLA, SLS, FDM), metals (DMLS, Binder‑Jet, EBM), and composites reinforced with carbon or glass fibers. Engineers can therefore match the mechanical, thermal, or chemical properties of conventional production plastics and alloys—crucial when low‑volume parts must integrate into larger assemblies.

Indian startup Agnikul Cosmos launched the world’s first rocket powered by a single‑piece 3D‑printed engine. Traditional production would have required dozens of welded components and six months of machining; Agnikul printed the engine in just three days, cutting lead time by 95 %.

Los Angeles‑based Czinger printed the structural nodes of its record‑breaking 21C hypercar and bonded them to carbon tubes, enabling geometries impossible with casting. Their parent company Divergent now licenses this digital factory model to brands such as McLaren and Bugatti, demonstrating how additive supports profitable low‑volume luxury vehicles.

|

Batch Size |

Recommended Processes |

Typical Materials |

Notes |

|

1–100 |

SLA, FDM, Metal DMLS |

Resins, PLA/ABS, 17‑4 PH |

Ideal for prototypes & bridge parts |

|

100–500 |

SLS, MJF, Carbon DLS |

Nylon 12, TPU, Rigid PU |

Powder‑bed yields consistent isotropy |

|

500–5,000 |

Binder‑Jet, Pellet FDM, Metal Binder‑Jet |

Stainless 316L, Low‑cost PA 11 |

Lower per‑part cost, fastest throughput |

|

5,000–13,000 |

Large‑format SLS, Hybrid Machining |

PEKK, Aluminum 6061 |

Approaches breakeven vs molding |

Analysts forecast the additive manufacturing market to reach $57 billion by 2028 as companies move toward geographically distributed, software‑defined micro‑factories. When tooling becomes optional and geometry is unlimited, production can occur at the exact quantity, location, and moment of need. This not only cuts cost and carbon but also democratizes manufacturing for startups and SMEs that previously lacked the capital for traditional mass production lines.

For organizations producing anything from customized medical devices to niche automotive components, 3D printing is no longer just a prototyping tool—it is the most practical, cost‑effective, and agile solution for small‑batch production. By eliminating tooling, slashing lead times, and enabling design‑driven innovation, additive manufacturing allows businesses to launch products faster, pivot with market demand, and stay competitive without massive upfront investment. As the technology continues to mature in materials, speed, and automation, its dominance in low‑volume manufacturing will only accelerate—making now the ideal time to integrate 3D printing into your production strategy.